Toilet Paper Roll Production Line

Description

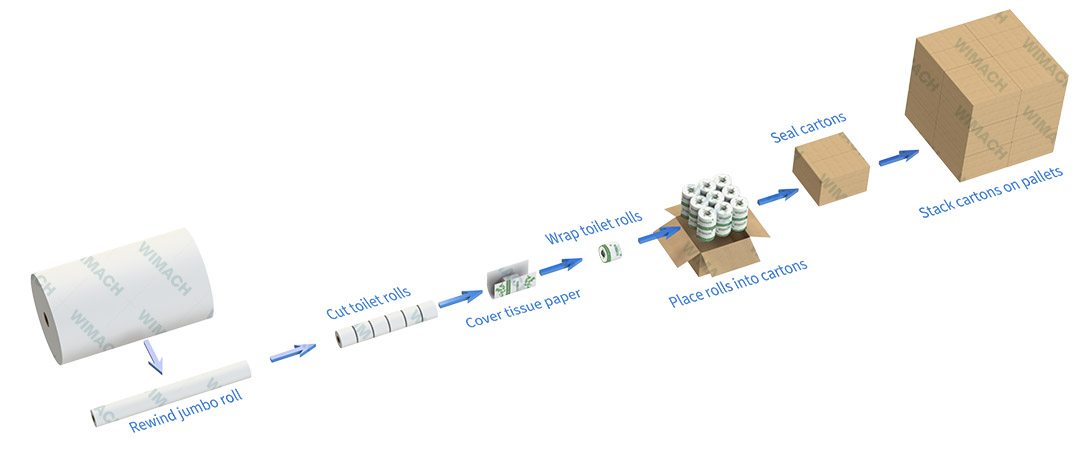

The toilet paper roll production line can produce toilet paper rolls, wrap toilet rolls with tissue paper, pack toilet rolls in carton and stack cartons on pallets automatically.

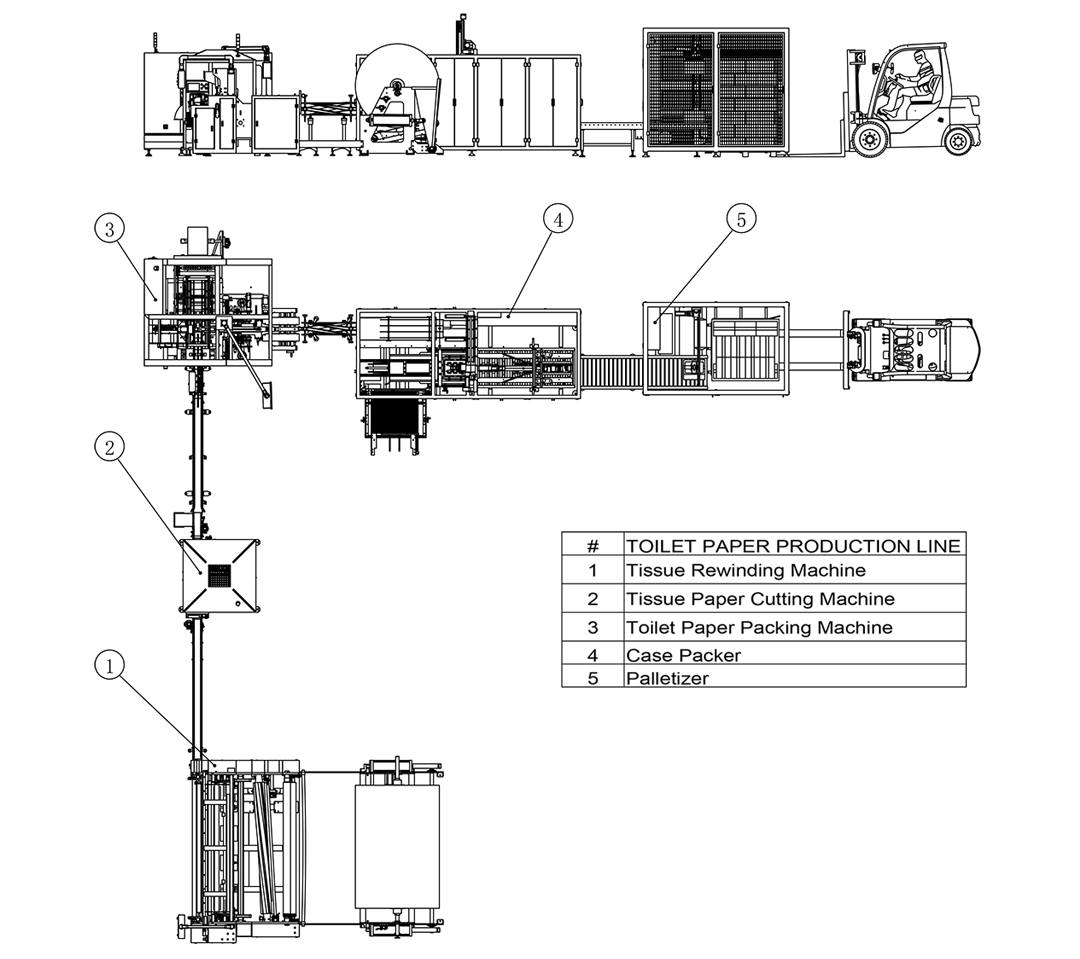

Toilet paper roll production line consists of a paper roll rewinding machine, a cutting machine, a toilet paper wrapping machine, a case packer, a pallet loader and conveyors. Toilet paper rolls are rewound and cut from the jumbo roll. All single toilet paper rolls are wrapped with tissue paper and then packed in cartons.

The production and packing speed are from 60 pcs/min to 120 pcs/min.

Rewinding machine: convert jumbo roll to small paper rolls; jumbo roll length: 1800 mm to 3200 mm

Cutting machine: 60 to 180 cuts/min

Toilet paper wrapping machine: wrap toilet paper rolls with tissue paper; packing capacity: 80 to 120 pcs/min

Case packer and palletizer: grab and place toilet paper roll into cartons and place cartons onto a pallet; packing capacity: 5 to 15 cartons/min

The production and packing line can be customized according to requests.

Toilet Paper Roll Producing Flow

Rewind parent roll -> Cut toilet rolls-> Cover tissue paper -> Wrap toilet rolls -> Place rolls into cartons -> Seal carton -> Stack cartons on pallets

Layout of the Toilet Paper Roll Production Line